ACTIVATED CARBON ( GAC ) FILTERS

Generalities

Filtration through granular activated carbon layer is an effective method for removal of organic pollution, taste, color, odor and free chlorine in raw water. This media works via adsorption process, whereby pollutant mole- cules in raw water are trapped inside the pore structure of the carbon substrate. On the other side chlorine

retention is essential to avoid damaging of reverse osmosis membranes by hydrolysis.

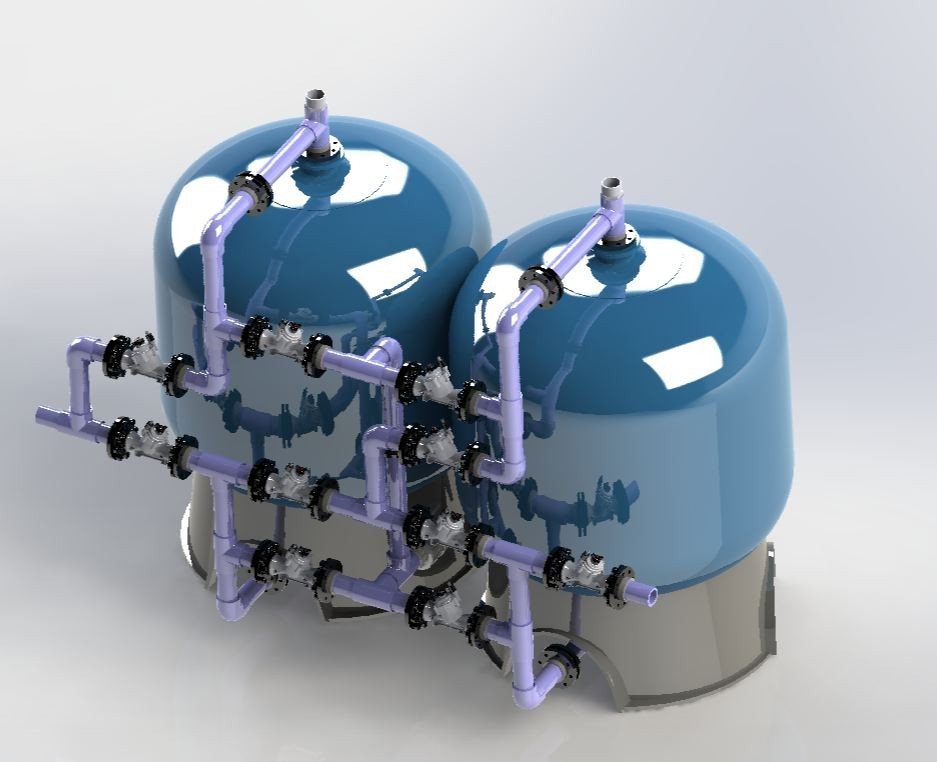

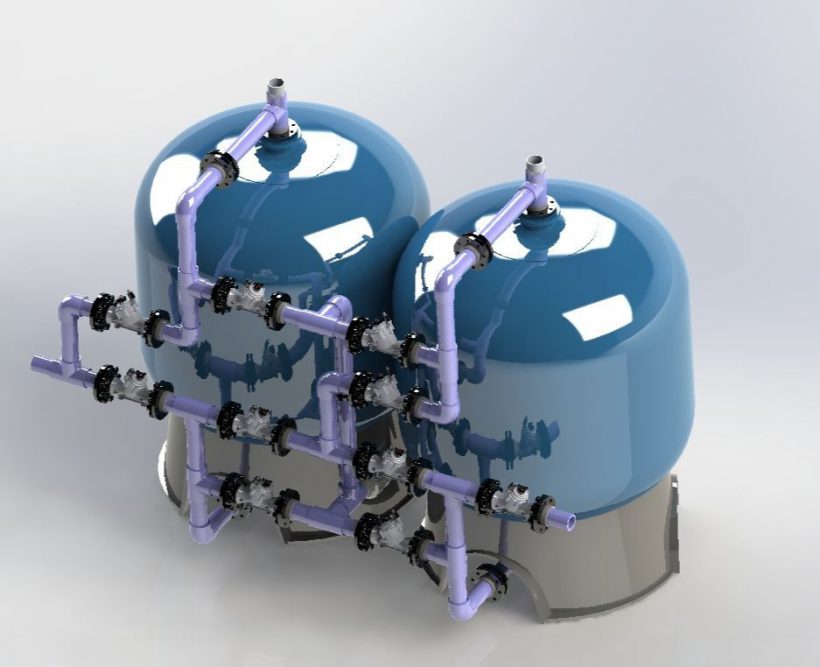

As for the case of Multi Media Filters, our GAC filters are fully automatic units. Filter’s service and backwash sequences are automatically controlled by the use of actuated valves via PLC based control panel or by the use of top mount control valves.

Filter’s tank are manufactured from Fiber Reinforced Plastic ( FRP ), from carbon steel coated with non solvent epoxy paint after sand blasting or from stainless steel ( all steel tanks manufactured according to EN 13445 standard ).

The choice of tank material, automation type and frontal piping material is conditioned by the treatment process and flow capacity.

Features

- Flow capacity : Up to 130 m3/h per filter ( For standard vertical

models. Pls contact us for horizontal steel filters)

- Tank Material : Fiber Reinforced Composite Plastic ( FRP ) or

Carbon / Stainless Steel according to EN 13445 standard

- Automation & Control : Pneumatic or electric actuated valves ( via PLC based control panel ) or top mounted electro-mechanical control valve

- Operational Pressure : 2 – 6 bar ( For standard vertical models )

- Frontal Piping Material : Stainless Steel, Galvanized steel , UPVC, PP

or HDPE conform to related EN norm

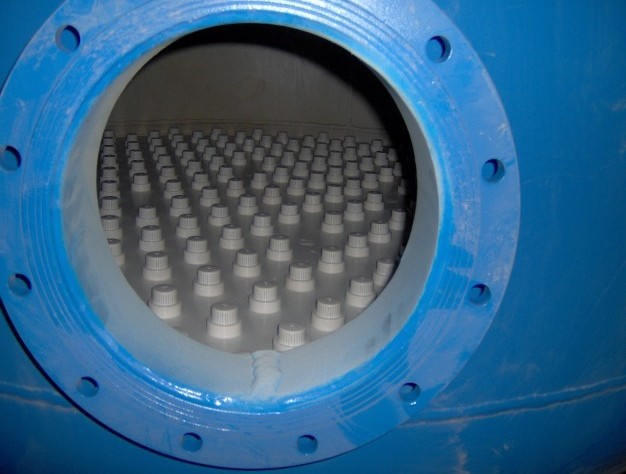

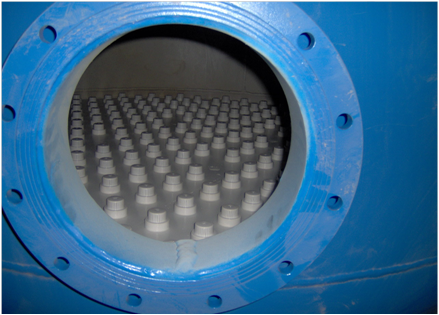

- Efficient water distribution and collection system inside filter tanks

including circular steel bottom plate and nozzle system

- Air vents, sampling & drain valves, pressure gauges as standard

instrumentation

- Neoprene coating ( 4 mm ) for internal surfaces ( Optional )

- Factory tested

İncelemeler

Henüz inceleme yapılmadı.